References

At Hydrive, we see ourselves as “research developers” because our years of industry experience enable us to work closely with our customers to develop sustainable cross-system solutions.

1,000 forage harvester tests in one night

Hydrive has helped Claas Selbstfahrende Erntemaschinen GmbH with setting up a Hardware-in-the-Loop test bench for a forage harvester using Vector products, in addition to creating a library of individual test steps that can be combined to produce further test scenarios. Over 1,000 tests have been programmed so far.

Control system for a valveless wheel loader

Energy-efficient drive technology reduces fuel consumption, cutting costs for users. To ensure user acceptance, these drive technologies must maintain the same standards of operability and machine performance.

Developing and commissioning a concrete paver

This paver is used to construct large concrete surfaces, such as motorways and airport runways, with a width of up to 15 m at a speed of approx. 1 m/min. Over 20 different hydraulic drives and a sophisticated control system ensure that the paver produces high-quality surfaces in terms of flatness and roughness.

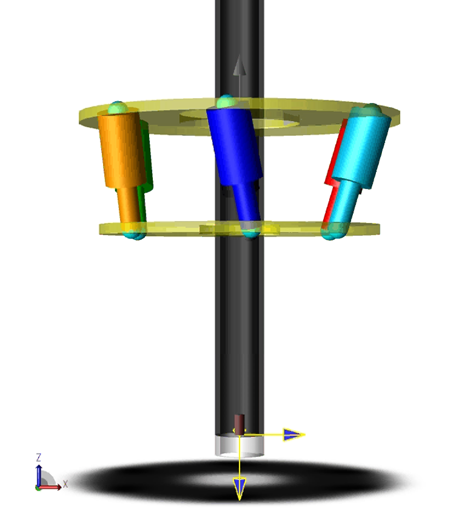

3D Modelling of Hexapod Manipulators

A welding robot was designed as part of a project for the development of a novel geothermal drilling process, to position tubes reaching a length of up to 12m and bond them with a force of more than 2,000kN. To minimise the development risk for the welding robot based on a hexapod manipulator, Hydrive supported several project phases with extensive simulations.

System optimisation of an active roll stabilisation

Hydrive’s engineers have created a detailed simulation model of a pressure control valve for a client in the automotive supply industry. This valve is one of the most important components in an active roll stabilisation system for high-class cars.

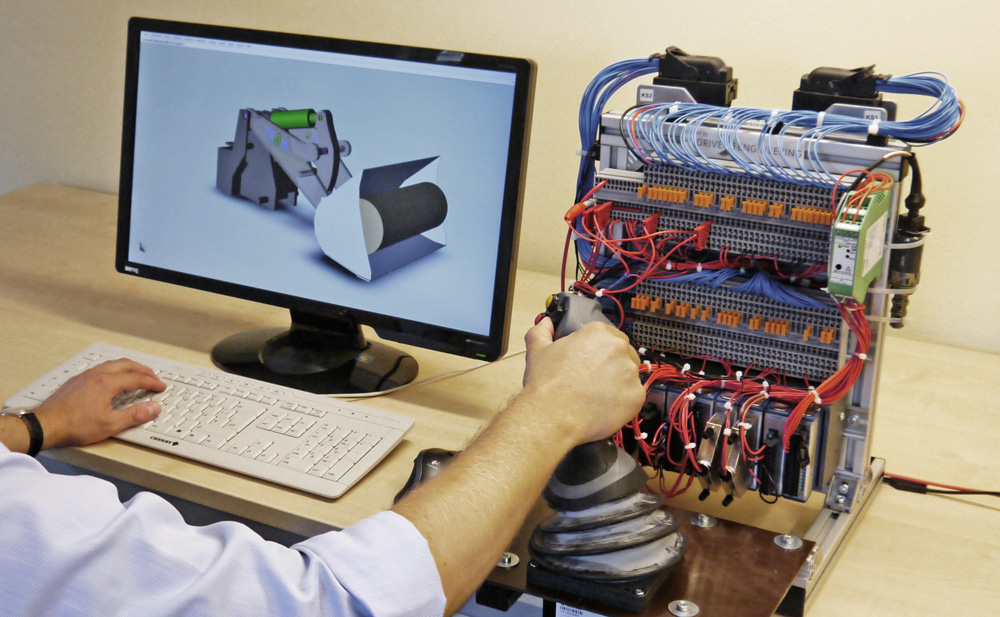

3D visualisation supports software development

As part of the joint project Developing Technologies for Energy-Efficient Drives in Mobile Machines (Entwicklung von Technologien für energiesparende Antriebe mobiler Arbeitsmaschinen – TEAM), Hydrive Engineering GmbH has added a 3D visualisation feature to a software test rig for the first time.